TUJ-560MEF / TUJ-630MEF

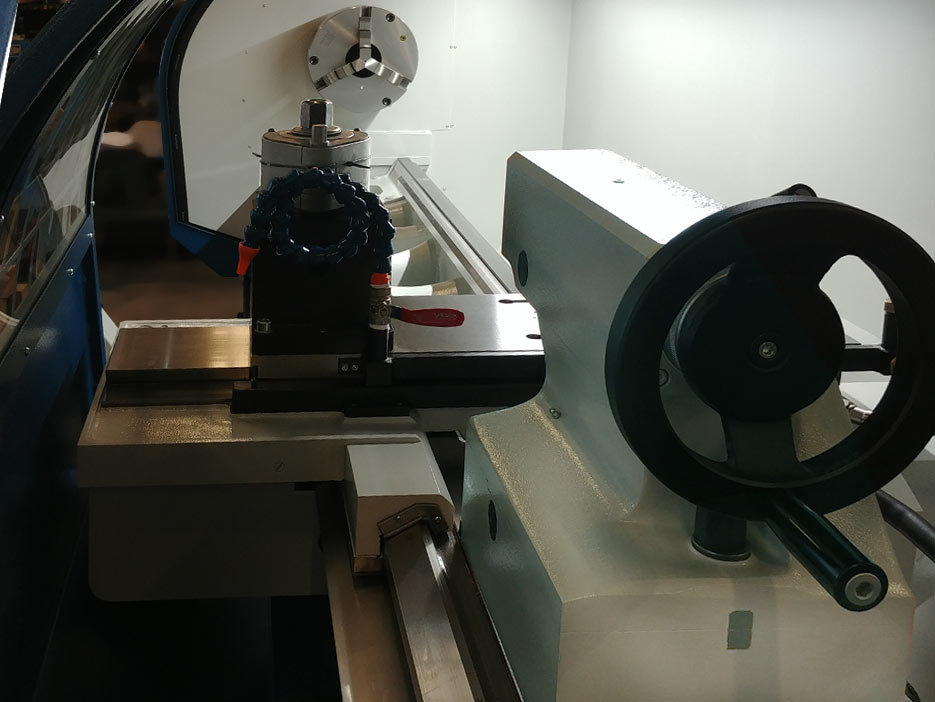

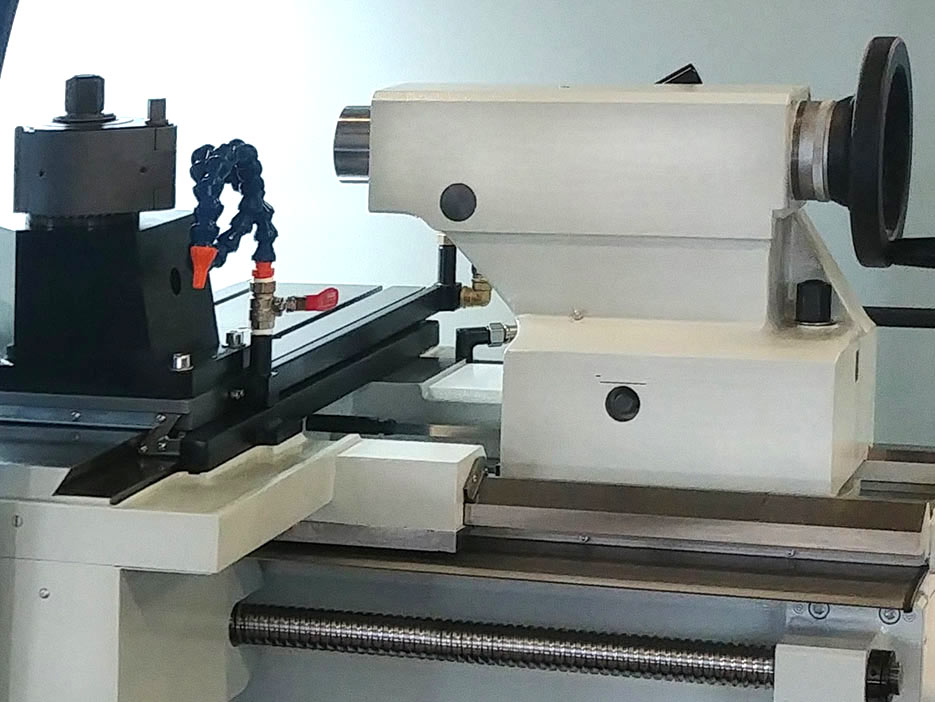

TUJ-560/630 MEF lathes machines with Fanuc 0i TF control system are intended to execute general turning operations one off’s and series production. Machine rigid construction, high power of driving motor and ball screws for slides drive, ensure a great capacity and machining accuracy.

Description

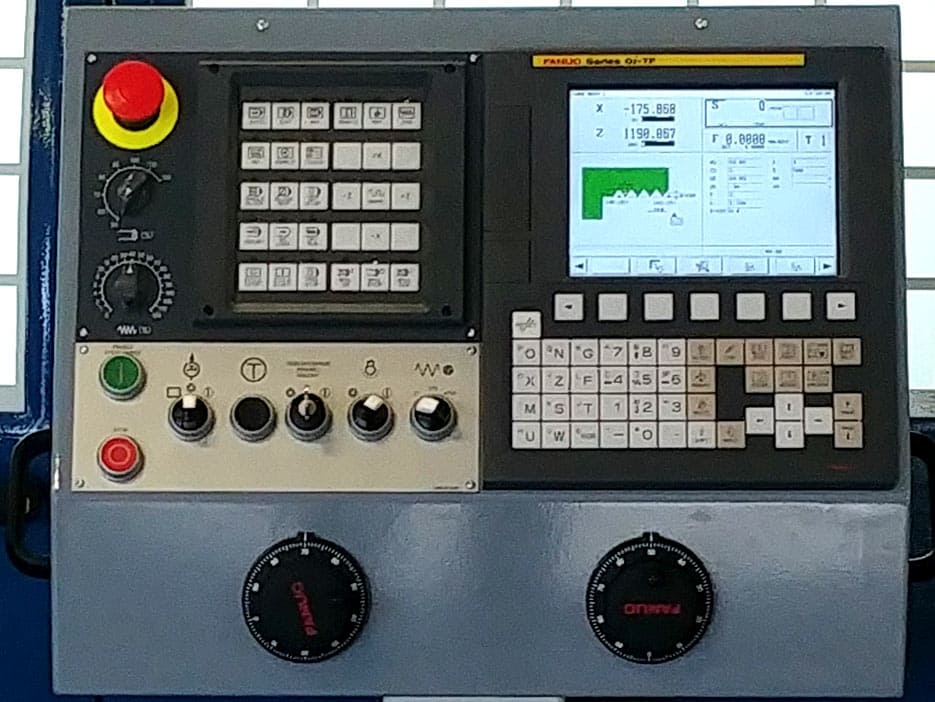

Control system enables work in conventional way (using manual handwheel), semi automatic with manual correction of cutting depth for each cut and automatic by recording machining cycle, setting a cutting depth and starting the cycle. Most of the elements used by operator during turning operations is spaced on a control panel slidable along the bed.

Additional display of the control panel enables simple setting of all essential parameters like: spindle speed, rate of travel, programming and cycle selection. Operator can see on the display entered parameters and tool position therefore he can go on with machining operations.

Spindle speed synchronization with slidable motor revolutions in axis Z allows executing a wide range of various threads.

Typical machining cycles available:

- Machining cycle acc to inserted geometry of machined surface

- Taper cycle

- Threading cycles: outer and inner threading, outer thread repair

- Grooving cycle

- External ball cutting cycle

- Drilling and tapping cycles

- Facing cycle

Possibility of operating CNC and manual mode. Tool selection and tool offset functions are available as well as constant cutting speed. There also exist a possibility of connecting an external personal computer by RS-232C interface.

Technical data

| WORKING AREA | TUJ-560MEF | TUJ-630MEF | ||

|---|---|---|---|---|

| L=1500 | L=2000 | L=3000 | ||

| Distance between centres | mm | 1460; | 1960; | 2960; |

| Max. turning lenght | mm | 1370; | 1870; | 2870; |

| Swing over bed | mm | 560 | 630 | |

| Swing over cross slide | mm | 340 | 410 | |

| Swing in gap * | mm | 800 | 870 | |

| Length of gap in front of driver plate * | mm | 250 | ||

| Top part of cradle width | mm | 370 | ||

| Max.weigth of detail fixed in centres | ||||

| Max.weigth of detail fixed in chuck 315 supported by tailstock | kg | 300 | ||

| Max.weigth of detail fixed in chuck and supported by steady rest | kg kg | 600 800 | ||

| Weigth | kg | 3160; | 3350; | 3760; |